What is the most common form of a cross-connection?

Ironically, the ordinary garden hose is the most common offender as it can be easily connected to the potable water supply and used for a variety of potentially dangerous applications.

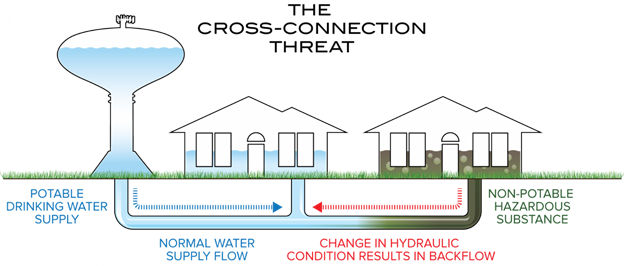

What is a cross-connection?

A cross-connection is a direct arrangement of a piping line which allows the potable water supply to be connected to a line which contains a contaminant. An example is the common garden hose attached to a sill cock with the end of the hose lying in a cesspool. Other examples are a garden hose attached to a service sink with the end of the hose submerged in a tub full of detergent, supply lines connected to bottom-fed tanks, supply lines connected to boilers.

What is continuous pressure?

This is a term applied to an installation in which the pressure is being supplied continuously to a backflow preventer for periods of over 12 hours at a time. Laboratory faucet equipment, for example, is entirely suitable for a nonpressure, atmospheric antisiphon vacuum breaker because the supply is periodically being turned on and shut off. A vacuum breaker should never be subjected to continuous pressure unless it is of the continuous pressure type and clearly identified for this service.

What is the difference between pollution and contamination?

Pollution of the water supply does not constitute an actual health hazard, although the quality of the water is impaired with respect to taste, odor or utility. Contamination of the water supply, however, does constitute an actual health hazard; the consumer being subjected to potentially lethal water borne disease or illness.

What is back-siphonage?

Backsiphonage is the reversal of normal flow in a system caused by a negative pressure (vacuum or partial vacuum) in the supply piping.

What factors can cause back-siphonage?

Back-siphonage can be created when there is stoppage of the water supply due to nearby firefighting, repairs or breaks in city main, etc. The effect is similar to the sipping of a soda by inhaling through a straw, which induces a flow in the opposite direction.

What is backpressure backflow?

Backpressure backflow is the reversal of normal flow in a system due to an increase in the downstream pressure above that of the supply pressure.

What factors can cause a backpressure backflow condition?

Backpressure backflow is created whenever the downstream pressure exceeds the supply pressure which is possible in installations such as heating systems, elevated tanks, and pressure-producing systems. An example would be a hot water space-heating boiler operating under 15-20 lbs. pressure coincidental with a reduction of the city water supply below such pressure (or higher in most commercial boilers). As water tends to flow in the direction of least resistance, a backpressure backflow condition would be created and the contaminated boiler water would flow into the potable water supply.

What is potentially dangerous about an unprotected sill cock?

The purpose of a sill cock is to permit easy attachment of a hose for outside watering purposes. However, a garden hose can be extremely hazardous because they are left submerged in swimming pools, lay in elevated locations (above the sill cock) watering shrubs, chemical sprayers are attached to hoses for weed-killing, etc.; and hoses are often left laying on the ground which may be contaminated with fertilizer, cesspools, and garden chemicals.

What protection is required for sill cocks?

A Hose Bibb Vacuum Breaker should be installed on every sill cock to isolate garden hose applications thus protecting the potable water supply from contamination.

Can an Atmospheric, Antisiphon Vacuum Breaker be installed on a hose bibb?

Theoretically yes, but practically no. An Antisiphon Vacuum Breaker must be elevated above the sill cock to operate properly. This would require elevated piping up to the vacuum breaker and down to the sill cock and is normally not a feasible installation. On the other hand, a Hose Bibb Vacuum Breaker can be attached directly to the sill cock without plumbing changes and at minor cost.

What is meant by “Degree of Hazard”?

The “Degree of Hazard” is a commonly used phrase utilized in cross-connection programs and is simply a determination on whether the substance in the nonpotable system is toxic (health hazard) or nontoxic (non-health hazard).

High and moderate hazards include such uses as metal plating process, hospital, nursing home, clinic, hotel, mortuary, laboratory, film processing, car washing, chemical process or storage, food processing, restaurant, irrigation systems, hair salon, sewage treatment, chemical fire protection, or any commercial building with the ability for occupancy changes.

Low hazard uses include single family residences.

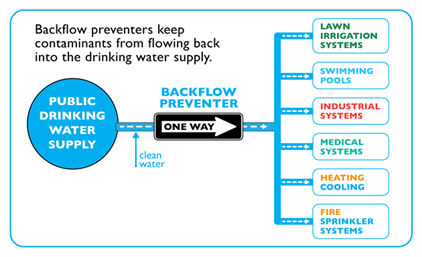

What are the five basic products used for protection of cross-connections?

The five basic products are:

1. Air Gap

2. Atmospheric Vacuum Breakers - which also includes hose connection vacuum breakers

3. Pressure Vacuum Breakers - which also includes backflow preventers with intermediate atmospheric vent for 1⁄2" and 3⁄4" lines

4. Double Check Valve Assembly

5. Reduced Pressure Zone Assembly

What is an Air Gap?

Air Gap is the physical separation of the potable and nonpotable system by an air space. The vertical distance between the supply pipe and the flood level rim should be two times the diameter of the supply pipe, but never less than 1". The air gap can be used on a direct or inlet connection and for all toxic substances.

What are typical applications for an Air Gap?

Because today’s complex plumbing systems normally require continuous pressure, air gap applications are actually in the minority. It should be remembered, however, that whenever a piping terminates a suitable distance above a contaminant, this itself is actually an air gap. Air Gaps are frequently used on industrial processing applications, but care should be taken that subsequent alterations are not made to the piping which would result in a direct connection.

Where is an Atmospheric Vacuum Breaker used?

Atmospheric Vacuum Breakers may be used only on connections to a nonpotable system where the vacuum breaker is never subjected to backpressure and is installed on the discharge side of the last control valve. It must be installed above the usage point. It cannot be used under continuous pressure.

What are typical applications for Atmospheric Vacuum Breakers?

Atmospheric Vacuum Breakers can be used on most inlet type water connections which are not subject to backpressure such as low inlet feeds to receptacles containing toxic and nontoxic substances, valve outlet or fixture with hose attachments, lawn sprinkler systems and commercial dishwashers.

Where is a Hose Bibb Vacuum Breaker used?

Hose Bibb Vacuum Breakers are small inexpensive devices with hose connections which are simply attached to sill cocks and threaded faucets or wherever there is a possibility of a hose being attached which could be introduced to a contaminant. However, like the Atmospheric Vacuum Breaker they should not be used under continuous pressure.

What are typical applications for Hose Bibb Vacuum Breakers?

Hose Bibb Vacuum Breakers are popularly used on sill cocks, service sinks and any threaded pipe to which a hose may potentially be attached.

Where is a Pressure Vacuum Breaker used?

Pressure Vacuum Breakers may be used as protection for connections to all types of nonpotable systems where the vacuum breakers are not subject to backpressure. These units may be used under continuous supply pressure. They must be installed above the usage point. Spill resistant models for indoor use are also available.

What are typical applications for Pressure Vacuum Breakers?

These applications should be similar to the Atmospheric Vacuum Breaker with the exception that these may be used under continuous pressure. However, they should not be subject to backpressure.

Where is a Backflow Preventer with Intermediate Atmospheric vent used?

These devices are made for 1⁄2" and 3⁄4" lines and may be used on non-health hazard cross-connections.

They are suitable for use under continuous supply pressure and possible protection against

backsiphonage or backpressure backflow

What are typical applications of Backflow Preventer with Intermediate Vent?

For 1⁄2" and 3⁄4" lines these devices are popularly used on boiler feed water supply lines, cattle drinking fountains, trailer park water supply connections and other similar low-flow applications. They will protect against both backsiphonage and backpressure and can be used under continuous pressure.

Where is a Double Check Valve Assembly used?

A double check valve assembly may be used as protection for all direct connections through which foreign material might enter the potable system in concentration which would constitute a nuisance or be aesthetically objectionable, such as air, steam, food, or other material which does not constitute a health hazard.

What are typical applications for Double Check Valve Assemblies?

Briefly, Double Check Valve Assemblies may be used where the degree of hazard is low, meaning that the nonpotable source is polluted rather than contaminated. The degree of hazard is oftentimes determined by local Inspection departments and, therefore, such departments should be questioned in order to comply with local regulations.

Where is a Reduced Pressure Zone Assembly used?

Reduced Pressure Zone Assemblies may be used on all direct connections which may be subject to backpressure or backsiphonage, and where there is the possibility of contamination by the material that does constitute a potential health hazard.

What are typical applications for Reduced Pressure Zone Assemblies?

This type should be used whenever the nonpotable source is more of a contaminant than a pollutant. Basically, they are applied as main line protection to protect the municipal water supply, but should also be used on branch line applications where non-potable fluid would constitute a health hazard, such as boiler feed lines, commercial garbage disposal systems, industrial boilers, etc.

Are there any regulations regarding cross-connections?

The State of Rhode Island Chapter 46-13-22 governs cross-connection controls. KCWA regulations can be found in Chapter 5 of our Regulations

What Standards are available governing the manufacture of backflow prevention devices?

Standards such as ASSE (American Society of Sanitary Engineering), CSA (Canadian Standards Association), AWWA (American Water Works Association) , IAPMO (International Association of Plumbing Mechanical Officials), apply to most backflow prevention products.

Is periodic testing required for Reduced Pressure Zone Assemblies?

Yes, and this is to ensure that the valve is working properly and is a requirement of many states and cross-connection control programs. Test cocks are provided on the valve for this purpose and manufacturers are required to furnish fieldtesting information.

Should a backflow preventer be installed in the water supply line to each residence?

Because of the growing number of serious residential backflow cases, many water purveyors are

now requiring the installation of approved dual check valve backflow preventers at residential

water meters. They are also educating the public concerning cross-connections and the danger of

backflow into the local water supply. Since water purveyors cannot possibly be responsible for

or monitor the use of water within a residence, the requirements for these cross-connection

control programs are increasing throughout the country.

What is a cross-connection control program?

This is a combined cooperative effort between plumbing and health officials, waterworks

companies, property owners and certified testers to establish and administer guidelines for

controlling cross-connections and implementing means to ensure their enforcement so that the

public potable water supply will be protected both in the city main and within buildings.

The elements of a program define the type of protection required and responsibility for the

administration and enforcement. Other elements ensure continuing education programs.